What kind of fabric is considered as high-quality? How to choose fabric? Introduce the fabric from several perspectives

1、Material

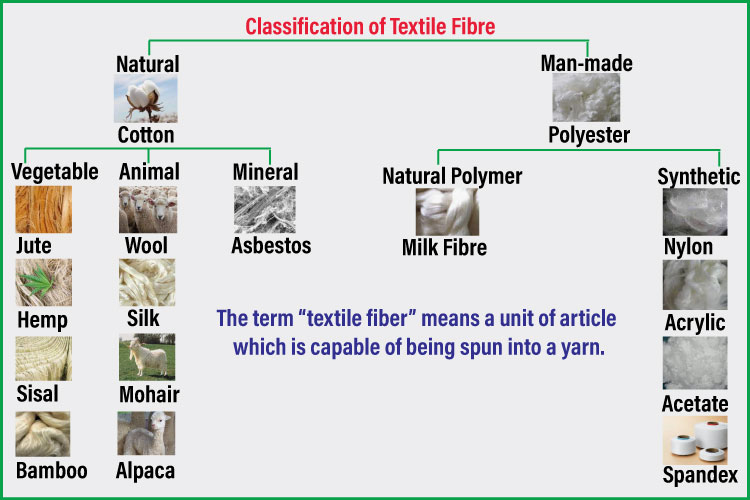

In terms of yarn materials, it is quite complex.I have attached a picture below to explain.

There is no superiority or inferiority among different components, only suitability. Blindly praising which material is good without considering the demand can be ignored. In the industry, fabric materials are generally divided into two categories: natural and non-natural. Natural materials are generally more expensive.

In our impression, everyone says that natural fibers are good and cotton and linen fibers are comfortable, but these materials are good materials for making ordinary close-fitting clothes or indoor clothing. However, when it comes to functional clothing, the advantages of chemical fibers are highlighted. Non-natural fabrics with functional processing are not necessarily cheaper than natural fabrics. For example, windproof and waterproof mountaineering jackets cannot be made with wool and cotton cloth. Also, the same material from different sources will have different prices, such as long-staple cotton from Xinjiang, which is more expensive than ordinary cotton because the fiber of Xinjiang cotton is slightly longer than that of ordinary cotton. The price of wool and cashmere on different types of sheep is also different, which is what businesses call a sense of luxury.

2、Spinning

There are many differences in spinning technology. Because I am not very familiar with spinning technology, I won’t elaborate on it here. However, the spinning method of yarn is a crucial link that causes fabric differences. Even different spinning methods of the same material can cause significant differences, such as combed cotton and ordinary cotton. You can understand that spinning is one of the most technologically advanced processes in the textile industry.

As someone who has been in the fabric industry for many years, I know that in-demand fabrics are in high demand starting from the yarn. Once, a Korean customer ordered fabric from us, and the agreed delivery time was two months, but the yarn for that fabric was also out of stock, and it took four months to deliver. Like other industries, this industry is also characterized by extremes. Good products are generally in short supply.

3、Weaving

From the perspective of weaving methods, fabrics can be divided into three categories: knitting, weaving, and non-woven fabrics. There is no superiority or inferiority among the three weaving methods. Different weaving methods are suitable for different uses. Masks are a typical product of non-woven fabrics. Knitting is an excellent choice for making underwear due to its softness and elasticity. The weaving method of weaving makes the fabric strong and reduces its deformation ability, making it possible to produce some stiff and stylish clothes. Let’s take a windbreaker as an example.

What kind of characteristics do we want the fabric of a windbreaker to have? 1. Stiffness; 2. Good softness; 3. Good breathability; 4. Good wrinkle recovery. Considering these four characteristics, we may not find a material that can meet all the requirements. Cotton is soft but not stiff, and it wrinkles easily. Polyester has stiffness and wrinkle recovery ability, but poor breathability. Smart humans mix these two materials together to make a composite fabric, using polyester for warp and cotton for weft, which can produce a composite fabric that has all the above properties. At this point, businesses can say that the fabric of this windbreaker is very advanced. But its essence is polyester and cotton.

4、dyeing proces

The dyeing process of fabrics can be divided into two types: pre-dyeing and post-dyeing. Pre-dyeing is the process of dyeing raw materials such as yarn or wool before weaving, knitting, or braiding. This results in a uniform color and good color fastness, which does not easily fade. Post-dyeing, on the other hand, involves immersing white or light-colored fabric into a dye solution after the fabric has been formed. As the fiber structure of the fabric has already been formed, the dyeing effect may not be as good as pre-dyeing, and the color may not be uniform, leading to poor color fastness and easy fading.

The choice of pre-dyed or post-dyed fabrics depends on specific needs and purposes. Pre-dyed fabrics have a more stable color and quality, usually suitable for high-end clothing and home decorations that require long-term color retention and no fading. Post-dyed fabrics have a wider variety of colors and tones, suitable for products that require more frequent dyeing and updating of styles.

The difference between cheap clothes found on online marketplaces and branded clothing lies in the dyeing and post-processing methods used. The presence of harmful substances such as formaldehyde, azo, and carcinogenic polycyclic aromatic hydrocarbons (PAHs) in clothing is regulated by the government, and the presence of these substances is more likely in clothes from online marketplaces. Therefore, if a seller claims that a piece of clothing has high-quality fabric, it’s important to understand exactly where the quality lies and whether it meets the needs and purpose of the clothing.

Conclusion

Although European and American fabrics are generally considered the best, Japanese and Chinese-made fabrics are also of good quality. Furthermore, Japan-made fabrics are often used by Chinese brands due to their cost-effectiveness and the ability to add brand value.

For high quality materials please visit ApparelX, a website that promotes transparent and barrier-free trade for fabrics and accessories.