How to choose the right material for your buttons! (Natural material, plastic, metal)

Hi, this is Daisuke an ApparelX news editor.

Today, I will explain about button materials and their shapes.

natural material

SHELL(SH)

Buttons are made from shells.

The shells are hollowed out, divided into different thicknesses, polished, and button holes are made.

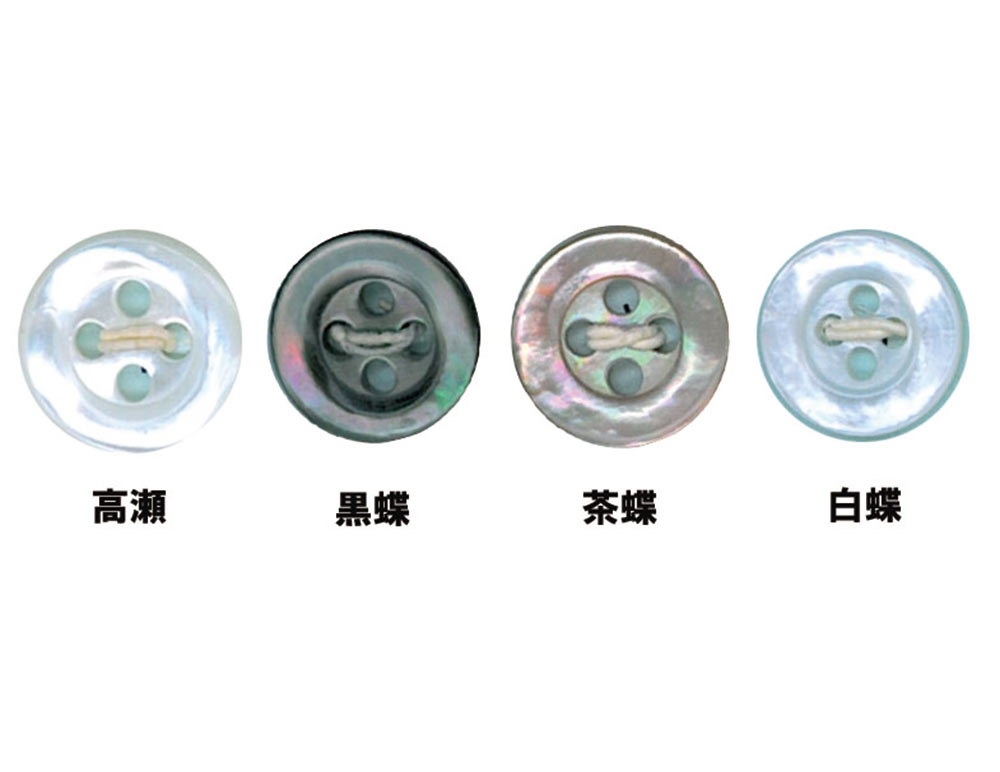

The four major types are as follows.

Takase Shell

More expensive than plastic buttons, but relatively inexpensive and most commonly used among shell buttons.

White-lipped Pearl

Another white shell button is the white-lipped shell, which is two to three times more expensive than Takase. In addition to being popular for its pearl-like brilliance, the reason is that Takase is made from large conch shells, while white butterfly shells are made from bivalve shells, so the amount of shells collected is small.

Black-lip Pearl

The color is grayish with greenish hues. The darker the black, the better the quality.

Tea-lip Pearl

For the brown type, there is a shell button made of two shells called brown clams.

Features of Shell Buttons

Shell buttons are a natural material, so even if they are the same type, no two are alike, and they have a beautiful shine that is different from plastic.

It has the advantage of making the clothes it is used on look elegant, but it is inferior to plastic in terms of durability because it is vulnerable to impact and breaks easily.

Since the main component of shells is calcium, dyeing is basically not possible, but dyeing can be done by coating the shells.

NUT(corozo)

This button is made from the fruit of the Tagua palm tree, and has a beautiful wood grain.

It is used for casual clothing such as cardigans and miscellaneous goods.

It is also called “ivory nut” because of the use of the pale cream-colored part inside the seed, which resembles ivory.

It is sometimes used in its original ivory color, but when dyed, it produces a pattern that resembles the annual rings that are characteristic of nut buttons.

Since the buttons are post-dyed, it is best to avoid using color schemes as they may transfer colors to other clothes if left wet.

Also, since it is made from coconuts, it absorbs water when wet and the acrylics seep out, staining your clothes, causing mildew and even cracking.

The color will change over time, but it can be said that the more you use it, the more it tastes.

Real Horn (HO)

水牛の角や骨を加工して作られます。ボタンの中で一番高価で、スーツなどに使われます。

角を輪切りにしてからくり抜いて加工する製法や、中空洞の角を切り開いて圧版状にして、それをくりぬいて加工する製法があります。

It is made from the horn or bone of a water buffalo. It is the most expensive of all buttons and is used for suits.

There are two methods: one is to cut the horn into a circle and then hollow it out, and the other is to cut open the hollow horn into a pressed plate and then hollow it out.

Different types of buffalo come in different colors, but the brighter colors are few and far between, and those that are lighter in color than black are more valuable and expensive.

It is durable, resistant to discoloration, and can continue to be used without changing its texture.

However, washing, sewing, steam pressing, etc. may cause the luster to fade.

Real Wood(WO)

There are various types of wood used for making them, such as boxwood, birch, ebony, and olive, but most of them are hardwoods, and are made by shaving or hand-carving a single piece of wood.

Nowadays, the most commonly used type is made of plywood, which is made of thin boards stacked with resin. 1 mm thick material made of birch, beech, lauan, etc. is soaked with phenol resin, dried, and laminated together to form the required thickness.

Plywood is also very durable and relatively inexpensive among wood materials. Some designs are baked with the grain of the wood to give it a burnt look.

Plywood buttons contain formalin and should not be used on clothing for infants under two years old.

Real Leather (LE)

It is made by pressing the epidermis of cows, horses and goats.

There are two main types of leather, chrome and shiv, but the material used for buttons is mainly shiv.

Basket buttons,” in which taped leather is woven into a basket-like shape, are often seen, especially on coats.

It is a natural material with a warm texture.

Plastic Material

Polyester (UP)

It is made of unsaturated polyester resin made from petroleum.

A manufacturing technique that can produce a luster similar to that of shellfish buttons was developed, and it became widespread as a substitute for shellfish buttons.

It is often used on shirts.

Because it is hard, strong, and easily formed into various shapes, a wide variety of buttons are available, and it is also used as a substitute for materials such as buffalo, shell, and nut.

Since it can be mass-produced, has a uniform finish, is inexpensive, and can be dyed, it is probably the most commonly used button.

Nylon (PA)

It is made from polyamide resin made from petroleum.

The most common method is injection molding, in which resin material is poured into a mold to create a shape.

It is highly resistant to both chemicals and solvents and is durable, but it is not very heat resistant, so care must be taken when ironing.

It is suitable for mass production, has a light specific gravity, and has the advantage of very good dyeability.

Casein (CS)

Although it is classified as a plastic, casein resin is a resin made from milk protein.

Rennet casein, one of the proteins in milk, is mixed with white pigment, pearl foil, and water to give it luster and color patterns, and then aged. The mixture is then kneaded together with heat and pressure, hardened into sticks, and processed into the shape of buttons.

Please note that formaldehyde is used in the process of making the material, so it is not suitable for baby clothes under 2 years old.

Since they are made from milk, they have a milky white soft luster and a warm texture that is a little different from other plastic buttons.

It has excellent strength and good dyeability, making it ideal for making original buttons.

In addition, casein resin is an environmentally friendly material because it is a “biodegradable plastic” that will decompose and return to nature.

Also called “Lact button,” “Lact” is a registered trademark of Daicel Chemical Industries, Ltd.

Urea (UF)

A synthetic resin produced by the reaction of urea and formaldehyde.

The material was developed to give the appearance of natural buffalo or nut, and the unique process of layering the materials in a plate form with colors and patterns to create the atmosphere of buffalo or nut is used. The material is extruded into long and thin tablets, which are then placed in a mold and molded by compression and heating.

Urea resin cannot be colored afterwards, so it is colored at the raw material stage and processed into buttons.

It is suitable for mass production and is often used for various items such as buttons for workwear and bottoms because of its excellent weatherability, impact resistance, chemical resistance, and heat resistance.

Because formalin is used, the molded product contains formaldehyde, so do not use on clothing for infants under 2 years old.

ABS

ABS resin is a copolymer of three components, A (acrylonitrile), B (butadiene), and S (styrene). It is a material that combines the characteristics of all three resins: the heat resistance, rigidity, oil resistance, and weather resistance of acrylonitrile, the elasticity of butadiene, and the gloss, electrical properties, and moldability impact resistance of styrene.

Although it is plastic, metal plating is possible. This is a feature not found in nylon or polyester.

It looks like a metal button, but since it is plastic, it is light and can be used on thin fabrics such as knitwear.

Metal

Buttons made of zinc, brass, and other materials.

It is used for uniform buttons and blazers.

But most brass buttons are made by combining two parts, the front part and the back part, and the inside is hollow, so even though they are metal buttons, they are not that heavy.

There are also casting methods using zinc, which can express even finer reliefs than brass.

Casting is one of the casting technologies, where molten metal is poured into a mold and formed, also known as casting. It has the advantage of being inexpensive to produce, but has the disadvantage of costly molds.

Rubber casting is a process that uses molds made of rubber. The cost of the mold is inexpensive, but it is not as durable as a metal mold.

Conclusion

Have you learned about the materials and characteristics of buttons?

ApparelX offers a wide variety of buttons, so please take a look.