Explanation about types of Eyelet and how to use them

Hi, This is Kayaba an editor of ApparelX News.

In this article, I would like to introduce the different types of eyelets and how to handle them, which you have seen before in clothes, bags, shoes, and the current trendy outdoor products.

Contents

Eyelets are metal or plastic rings that are attached to fabric, leather, vinyl, or other material to reinforce the holes in the material to prevent tearing. Attaching these parts reinforces the area and prevents it from being torn or damaged when string is threaded through it.

To install Eyelets, you will need a special tool. Also, if the dovetails and the tool do not match, it will not be possible to install them neatly.

Types of eyelets

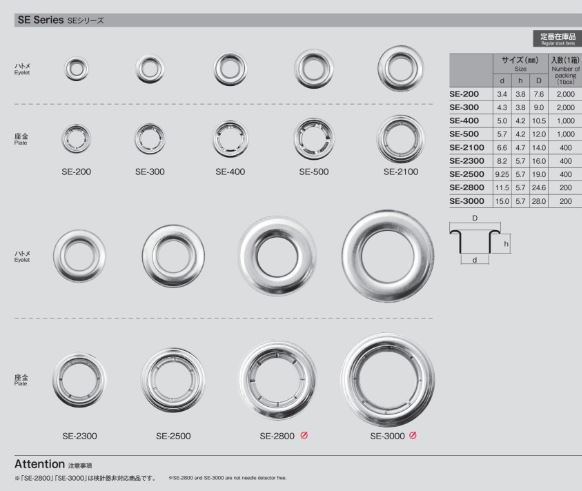

Standard type

This is the standard type. It is probably the most common shape that you have seen.

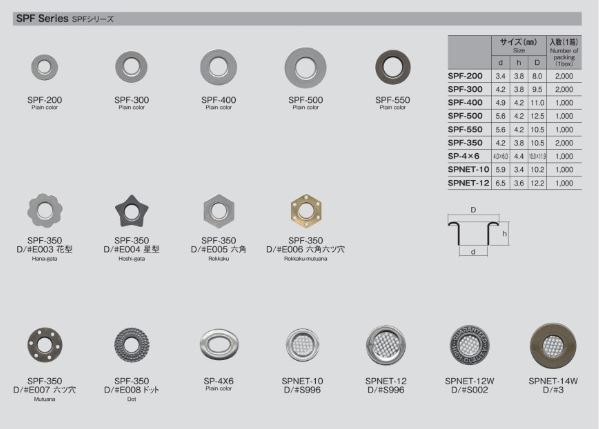

Flat type

This type is characterized by a cleaner appearance than the standard type because the part that appears on the surface is flatter. There are two types: the punched type and the type that requires a tip hole. There are also those with decoration and those with mesh.

Oval type

It is necessary to make holes of the same shape in the fabric beforehand. The holes can be used to thread wide tapes or ribbons, or large ones can be used for the handles of bags.

Grommets

This is a dovetail that can be used for bags, tents, sheets, car mats, etc. This product is not compatible with needle inspection.

How to install eyelets

In this section, we will introduce the types of eyelets and their mounting types, mainly for clothing.

I will explain using the products of “Morito Japan Corporation”, which we also deal with.

A hand press machine is a special machine for attaching parts with special frames. It can be used not only for eylets, but also for dot buttons and mechanical fastener.

Some fabrics may not perform well due to their thickness or processing, so be sure to test the fabric you will be using.

Fit the above parts into the bottom frame and hit it.

The lever is like leverage, allowing for smooth installation of eyelets with light force.

This is a handy machine if you are installing large quantities.

Some sewing factories are equipped with automatic machines to handle large quantities of products that cannot be handled by hand presses.

However, due to the nature of this machine, the places where the fabric can be pressed are limited, and it cannot be installed in the center of the machine or other hard-to-reach places.

The first step is to fit the frame into the hand press machine.

Installation is easy, either with screws or by simply fitting them into the holes.

Set the parts there. The upper side is the part that will be on the front, and the lower side is the washer. Be careful not to mistake the front and back of the washer.

After confirming where the eyelets will be attached and the back and front of the fabric, press.

Ideally, the protrusions on the front part should curl up nicely when looking at the back side as shown in the image.

If you are able to press well but the eyelets turn, or if they come loose when you pull on the fabric, you can always add rubber seal to solve the problem in most cases.

Thanks for reading!

In this article, I used MORITO dot buttons as a reference, but there are also other manufacturers such as Gondola Shoji and YKK snap fasteners, so why not choose the one that best suits your needs and specifications?

At ApparelX, you can purchase eyelets, frames, and hand presses from various manufacturers.